SUMMER BLOG 2022 : THE SAWMILL

The Sawmill

Timber

I source my timber from local sustainable sawmills. The sawmills season, cut and prep the timber ready to be used for our requirements.

When I select the timber from their stacks for a piece of furniture, I have to consider the following.

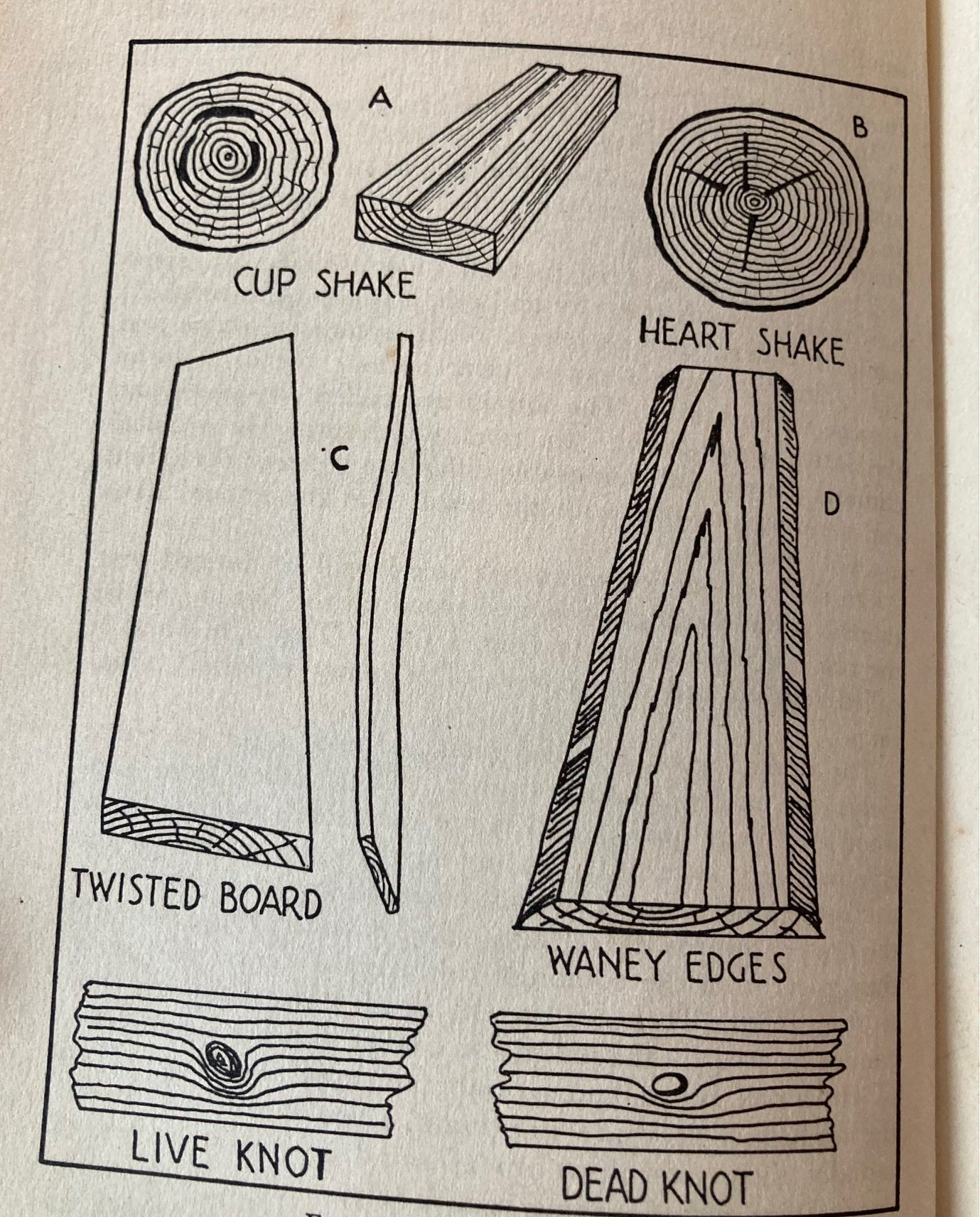

Defects in timber

Defects in timber are common.

Here are a few below.

Shakes appear due to shrinkage.

Twisted or boards in wind are due to stresses in the tree that are released when the trees are sawn.

The twist can also occur when the boards have been stacked incorrectly.

Knots are the remains of twigs, branches or boughs.

Knots, twisting and shakes can make machining timber awkward.

The Seasoning

The UK has a temperate climate and usually trees are felled in the winter

The winter is the time of year when the moisture in a tree is at its least. Even cutting the tree down at this time of year, you will find that 30% of the weight of the tree is moisture. A sawmill will season the timber by drying the wood slowly and reducing the moisture level.

Reducing the moisture level is important and will allow the timber to be used for making furniture, joinery and timber frame buildings.

The outer of the tree will dry faster but the centre will take much longer. To help the moisture come out of the tree faster the tree would be cut into planks.

The timber boards would be stacked on top of each other with sticks between to allow the timber to air dry.

The seasoning will take different amounts of time, depending on thickness of the boards and type of timber being seasoned. The moisture content needs to drop to 18% for Air dried timber which can take 1-3 years. The timber is ready for the next stage kilning. You can continue to air dry for 8 years and moisture level will drop to 8%

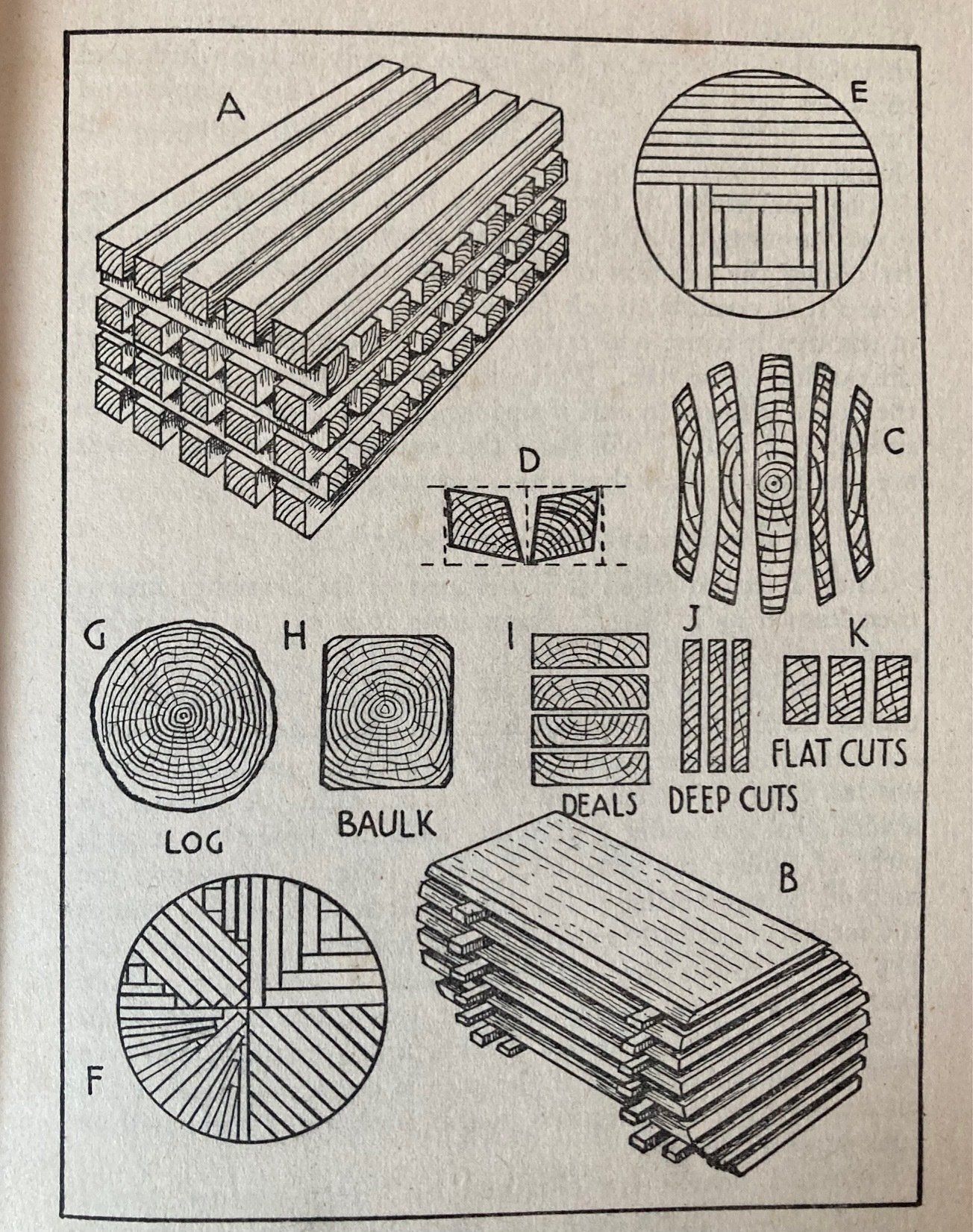

Illustration from Woodwork by W.L. Showell

The Kiln

To increase the speed of drying timber a kiln can be used. A kiln allows the temperature, air flow and humidity to be controlled.

Allowing more moisture to be removed from the timber faster. A few weeks instead of a few years. The moisture content will drop to 12% to 8%.

The removal of moisture and drying means the timber boards will shrink. The timber boards are cut larger in thickness to allow for the shrinkage. The tree log is cut to get the maximum boards out of the tree.

The timber will be sold either as quarter sawn or crown cut boards. Quarter sawn is more stable and crown cut is more figurative but is prone to cupping. Depending on how the annual rings structure has been cut through.

I can now go pick up your timber from the sawmill as the timber is ready to be used to make a piece of furniture.

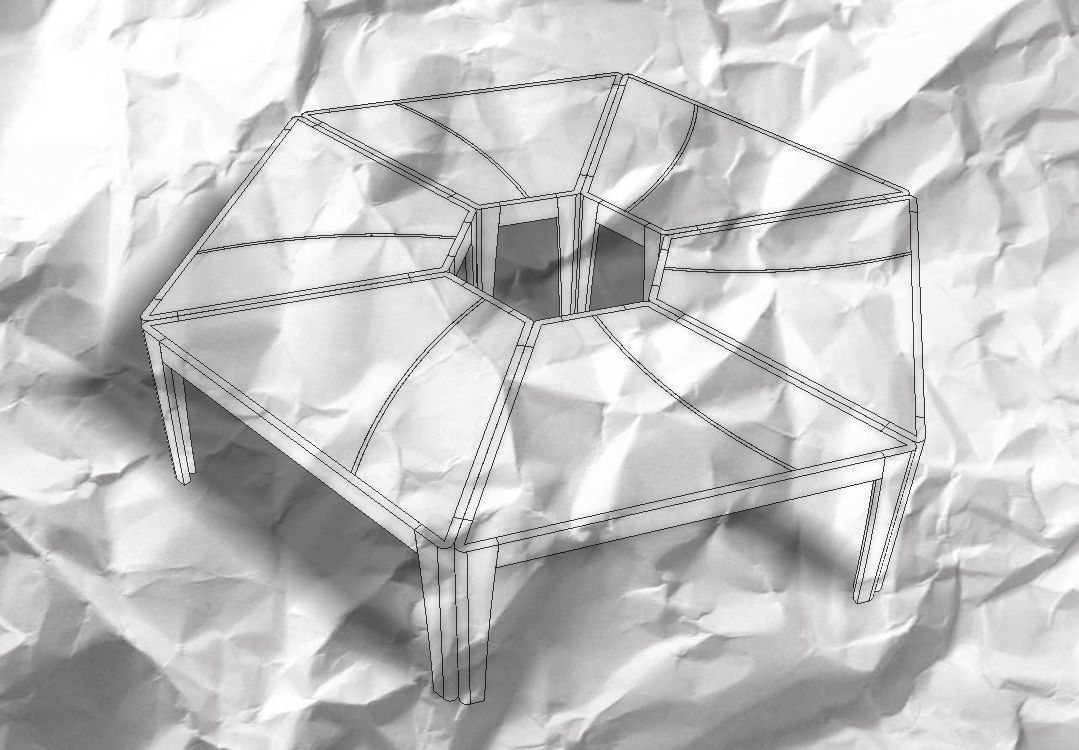

Welcome to my new blog series!!

Check out my next Autumn blog in October/November

by Anna Nichols

Following Anna in her design studio, workshop and at local sawmills selecting timber